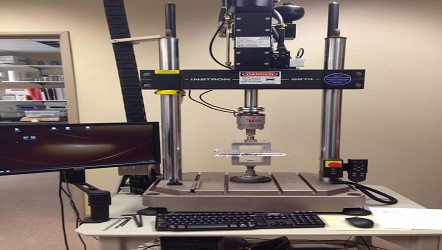

The core of everything world-class is 'Quality' and at Rameshwar Metal India, our commitment to quality applies to each product and each process. Our Research and Development facility is equipped with state-of-the-art facility to conduct metallurgical and mechanical tests to ensure highest standards of output. Our Qa Internation Certification Ltd amplifies our constant endeavors towards achieving effective Quality Management Systems.

On the materials procurement front, we ensure that our raw materials are sourced from only trusted vendors of international repute. We further assure the implementation of strict quality protocols at each step of our production process and conduct post production tests as well, to reinforce our commitment towards quality.

Our core qualitative approach is further strengthened by the fact that our products are offered after approval of renowned engineering consultants, Inspection agencies and statutory authorities like Lloyds Register, Bureau-Veritas, Tata Projects, Toyo Projects & Development India, IBR, SGS, RITES, Jacobs H & G and Bax-Counsel.